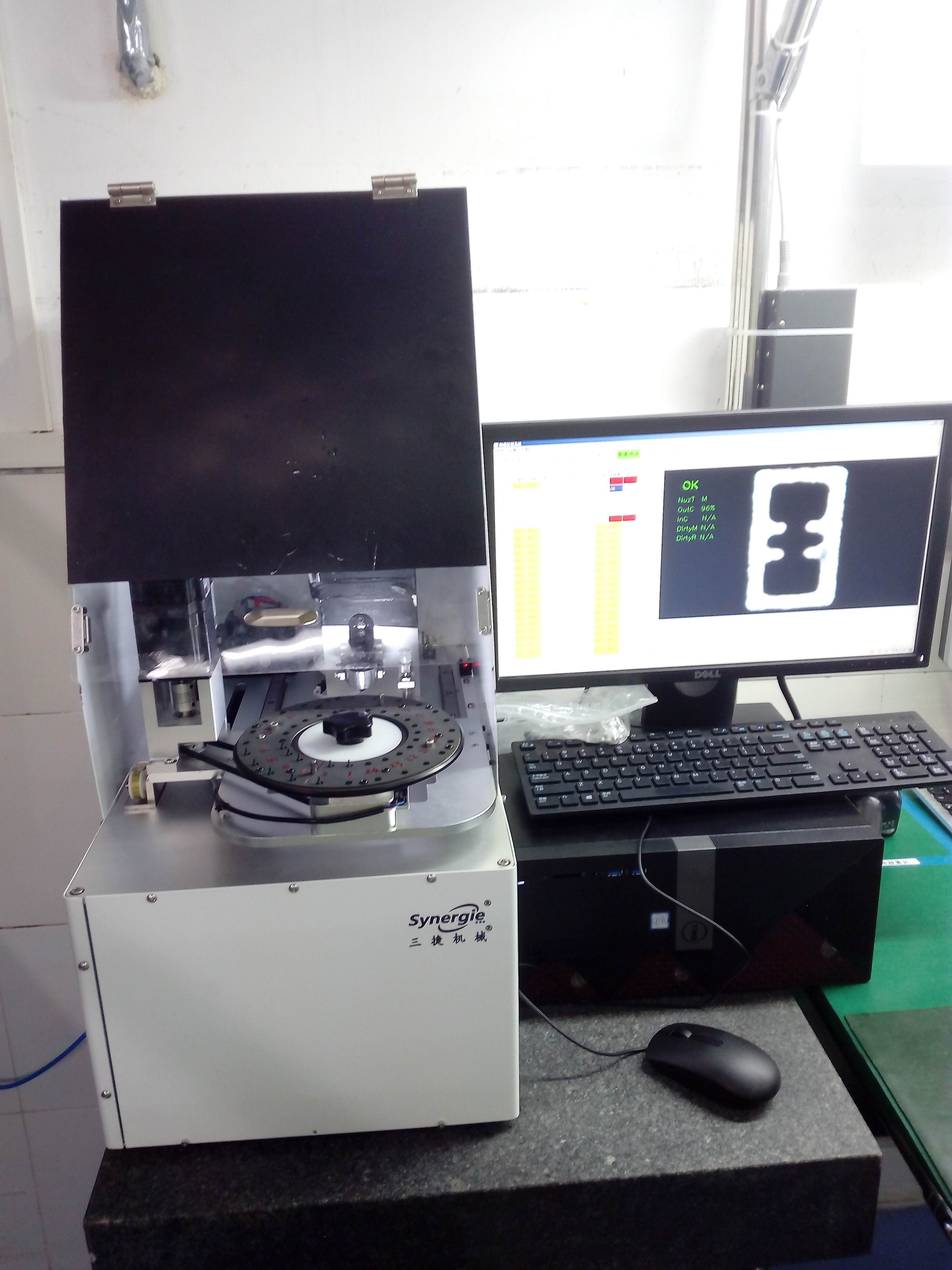

NI-18系列吸嘴检测机成功推出

智能吸嘴检测机,是深圳市三捷机械公司历经3年研发,新近推出的一款针对SMT行业主流贴片机吸嘴进行自动检测的精密仪器。设备采用先进光学检测技术,加上智能控制软件,可对不同型号的吸嘴进行表面、内孔、真空度进行检测,从而对吸嘴状态做精准判别。并可读取二维码,与MES系统联机实现电路板贴装全过程控制。

随着消费者对电子产品的小型、智能化的需求,电子元件的尺寸也变得日益轻小。贴片机吸嘴的尺寸已越来越接近人工目测的极限。相比于传统的人工检测,智能吸嘴检测机的检测范围从直径0.1mm到3.7毫米,帮助客户的品质管控再上新台阶。

With 3 years development by ShenZhen Synergies Machinery, the Intelligent Nozzle Inspector (INI) is an accurate inspection instrument which aims to inspect the SMT nozzles from the mainstream SMT machines. It combines advanced optical inspection technology and intelligent software algorithm to carry on surface scan, inner-hole and vacuum detection, so that the status of various types of nozzles can be precisely justified. By introducing the INI machine, the unique bar code from different nozzles can also be processed. Together with the inspection results, each nozzles status can be linked to the customer’s Manufacturing Execution System (MES), and realizes the full-time control of the pick and placement process.

Due to the rapid growth of the consumer electronics, more light, durable and powerful products are becoming new trends to the customers. This appeals to make the electronic components to be more and more tiny. Meanwhile, the miniature size is almost reaching human’s discriminating limits, thus the INI machine is becoming a must to customers’ SMT process.

Compared to the human inspection, the inspectable nozzle size of the INI machine ranges from 0.1mm to 3.7mm, and no longer relies on operators’ evaluation, thus improves the customers’ quality assurance.

适用机型:富士NXT系列、环球、松下、西门子等主流机型;

Applicable Machines: Fuji. Universal, Panasonic, Siemens

主要检测指标:

Main indicators:

吸嘴真空度检测,精度可达+/-100Pa;

Vacuum inspection: +/-100Pa

二维码读取;

Bar code reading

吸嘴表面:破损、脏污、裂痕;

Nozzle surface detection: Contamination, scar,

吸嘴内壁:脏污、堵塞

Inner hole detection: blockage, contamination

主要优点:

Main advantages:

表面及内孔清洁度检测;

Surface and inner hole inspection

适用市面上所有主流贴片机吸嘴,通用性强;

Versatile and suitable for all main-stream nozzles.

可与MES联机,实现所有吸嘴状态在线监控;

Be able to link to MES for real-time monitoring

可对每个吸嘴单独读取二维码,并对状态进行保存;

Be able to read QR code and save status for each individual nozzle

机器判别吸嘴状态,消除人工误判;

Nozzle evaluated by artificial intelligence, no longer rely on operator.

操作界面简洁易用,无需复杂培训;

Easy user interface, no sophisticated training needed;

维护简便,无耗材费用

Easy maintenance, no consumable cost;

SMT自动化行业从业二十年,强大的软件支持团队,确保后续升级服务;

20 years SMT automation experience, strong software support, ensures future upgrades.

设备主要参数:

Main Parameters

外形尺寸:600X500X700mm;

Outline Dimension: 600X500X700mm

重量:30Kg;

Weight

单次循环最大检测数量:24只;

Max. nozzle inspection for each cycle:24

气源:0.5MPa;

Air pressure: 0.5MPa

电压:AC220V

Voltage: AC 220V